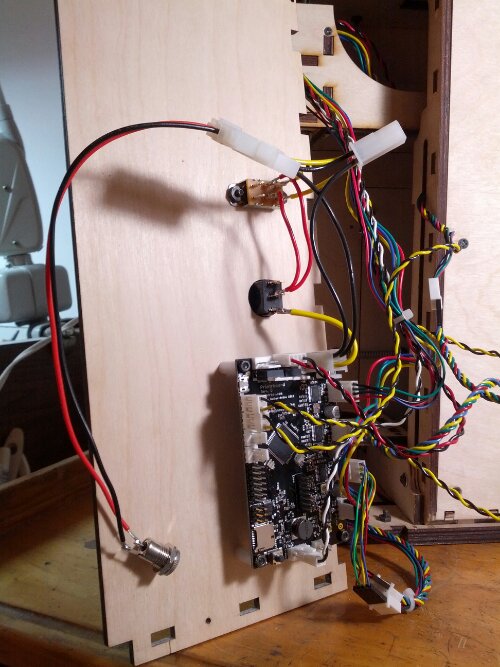

So the wiring was a little kludged together but I didn’t have the patience to wait for the wiring solution Brook told me he’d put together for me, so I hacked something together to get the thing up and running using some bits from Radio Shack.

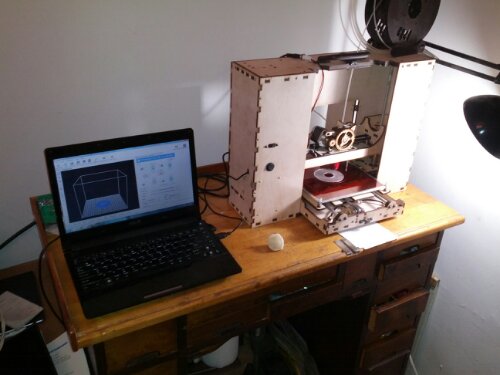

I was pretty sure that the power supply which came with the bot would be underpowered for the heated bed, at least for ABS type temperatures, so after getting a tip from Brook that an X-box 360 PSU might work (the original version puts out 203 watts) I had ordered one and also a broken motherboard to pull the socket out of, both from eBay of course. Couldn’t wait for that though, so I fired it up with some glow-in-the-dark PLA without even calibrating anything to see what it could do.

I had a couple restarts while I tried to figure out how to tell the bot what Z = 0 looked like without the end stop yet installed, but eventually got a first layer to stick using hairspray painted on polyamide tape and sat with a mile wide grin listening to the robot sounds.

To make sense out of my aural joy, I should explain that I played guitar in an art punk band for about 10 years and machine sounds were a frequent inspiration for my band mates and me. Hopefully the video captures a little something of what this wonderful beast sounds like, but if you’re into challenging music, imagine Glenn Branca meets Autechre. Or just imagine a very early dot matrix printer with another axis thrown in. It is truly a brilliant symphony of motors, belts and creaking wood.

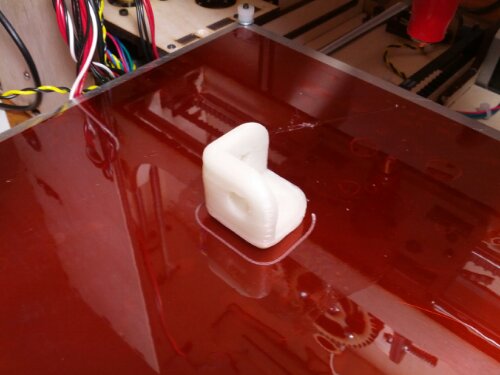

It was lumpy, had some fallen perimeters where it maybe should have had support, but gosh darn it it came right out of my head and onto the print bed in 3 dimensions.

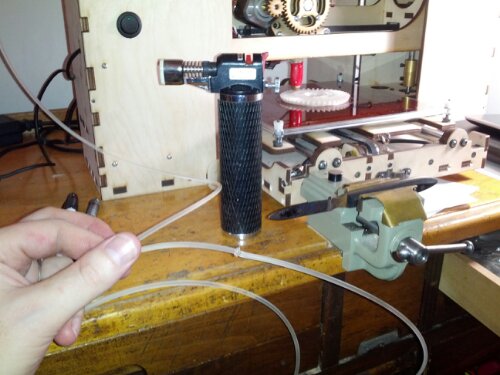

It was pretty obvious I had to calibrate the extruder (this is the process of telling the software how much filament is extruded by each turn of the extruder motor), but try as I might, I couldn’t get consistent results during these calibration checks. On close examination, it appeared that the hobbed bolt was slipping on the PLA, so I took is out of the extruder to find the knurls were already packed with PLA particles.

I’m pretty sure this was caused by running it with too little tension, as the first slip or two will grind up some plastic into the knurling and make slipping all that much more likely going forward. I decided though that since I already had the bolt out, why not try to improve the (pretty sketchy looking) teeth. I won’t go into details, as this is a 3d printing blog, not a machining blog, and besides, if you have the tools and ability to do such a thing you probably don’t need me to tell you how. But anyway, this is how it looked when I was done.

So that done and reinstalled, I was able to calibrate the extruder and attempt to print something for real. It’s worth mentioning that there was a lot of frustration involved in getting the software to cooperate, getting the bed close to level (installing the Z end stop helped), keeping the wires from binding inside the confines of the box, etc. When my first proper print started sticking to the bed, it was a feeling of tremendous accomplishment.

I had switched to clear PLA and cut off a portion of it when it got tangled and about 40 minutes into the hour and ten minute print I started to get nervous that it would run out of filament. In a fit of fear and inspiration I decided to try the same trick watchmakers use to splice lathe belts together.

I put a knife on the vice and got it good and hot with a micro-torch and dragged the tips of the two pieces of PLA up off the blade and into each other and then held them that way while they cooled. After a little trimming with a utility knife to smooth out the bulging goo around the splice and a quick sanding to further smooth out the joint, the connection looked like it would sneak through the extruder.

Wouldn’t you know it? The bot stopped working before the print was completed anyway. Not sure what happened, the thing just stopped and Repetier-Host (the software driving the thing) didn’t even know anything was amiss. I finally just had to turn it off and restart everything. Tried a few more times but each time it just stopped after a few layers in the same fashion. Still not sure what happened, but I’m kinda hoping it’s the wimpy power supply crapping out? That’s OK, I had lots more work to do anyway, so waiting for the X-box components wasn’t gonna kill me.

Amazing. Truly impressive. Even more impressive than St Andrews (or something…right?), and that’s saying something!