OK, I’m just gonna go ahead and be the precocious jackass who spits out an idea irrespective of the knowledge and experience to know if it’s been done before, doesn’t make any sense or is otherwise moronic or irrelevant: dynamic directional extrusion. You’re welcome.

My understanding of the way material is extruded through a hot end on your standard fused filament fabrication (FFF) 3d printer is that the nozzle remains roughly perpendicular to the bead of material it is laying down, requiring that the extrusion be as consistent as possible through all 360° of movement that may be involved in a single print. It kinda smears the molten material onto the bed or the preceding layers and the shape and size of the bead depends on the material, temperature, size of the nozzle, extrusion speed, layer height, travel speed of the hot end, etc. It’s this delicate and dynamic balance of inputs in fact that makes the difference between crude or merely adequate prints and truly high quality fabrication (did I mention that I don’t even have a damn printer yet? please see sentence number one and deride me appropriately in the comments).

OK, so why not have a nozzle shaped to extrude more precisely and out of only one side, connected with a stepper drive to adjust the angle of the nozzle relative to the travel of the hot end as it’s laying down material? If it’s traveling only in the positive x direction, the opening in the nozzle would be pointing in the negative x direction so that you’re laying down a precisely shaped bead rather than a shmear (sp?). Surely this could give you more precisely controlled details. I mean, since I thought of it and all.

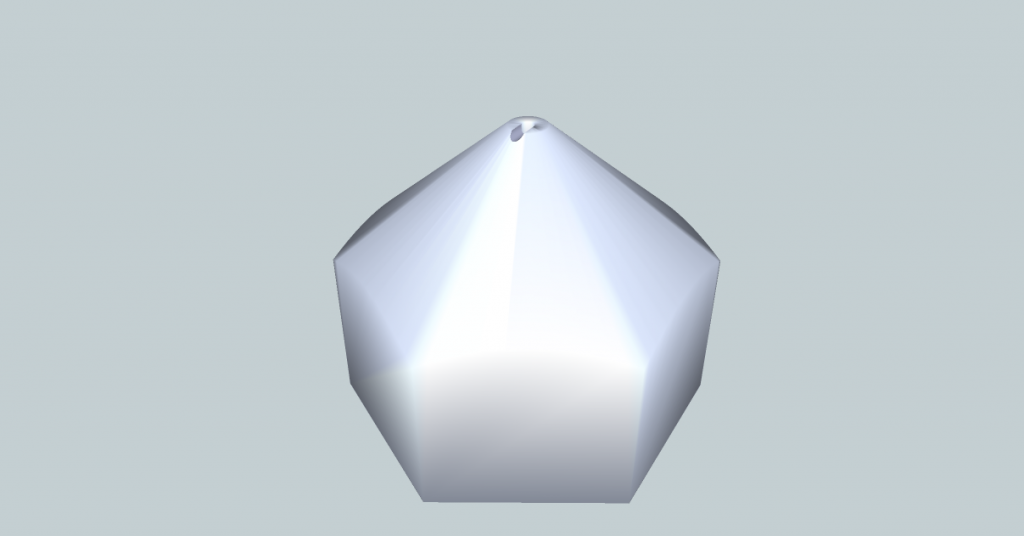

Here I have hacked together a sketch of what I have in mind by modifying the nozzle design from wildBill’s budaschnozzle from Thingiverse (a “for reference only” representation of the Lulzbot design).

OK, I just checked and somebody else already thought of it. More to the point, they patented it already soo… You know, proceed with caution:

Directional Extruded Bead Control

But once you have a dynamically aligned (or otherwise directionally controlled) nozzle, think of the other possibilities! Have you seen the video of RIchRap printing with three different filaments?

If you perform such a thing with a dynamic nozzle, couldn’t you truly “blend” the colors? Rotating the nozzle back and forth during the print should give you a mixing type action that could conceivably be used to make true color prints from three (or more) basic colors, no?

OK, I’ll leave the comments wide open on this post if I can figure out how to do that so that it’s easier for the patent holder (or his legal representation) to get in touch with me and for other knowledgeable folks to drop some knowledge on me. If you’re only input is to call me a jackass, please see sentence number one.

🙂

For me there is no doubt that what you describe can be done – mechanically.

I work around a fair amount of robotics, but my plastics knowledge is limited to injection molding on machines from 85-T to 1250-T, so I know nothing of the physics of printing. I’ll learn though because I’ve signed up for the Lifetime Subscription to your blog.

A more imminent question for me is how to get a 5-minute video accessed through Facebook to play in less than 15-minutes. We need a better video extrudes as well.